In the realm of product design and its interplay with electrical noise, electromagnetic interference (EMI) and electromagnetic compatibility (EMC) invariably emerge in conversations. Frequently, there lies a perplexing question: “What sets EMI apart from EMC?” The answer, while seemingly straightforward, veils itself in ambiguity, for there is no universally accepted definition for either term, rendering them somewhat interchangeable.

The International Electrotechnical Commission (IEC) puts forth its perspective on EMC, defining it as the “capacity of equipment or a system to operate satisfactorily within its electromagnetic environment, without introducing insufferable electromagnetic disturbances into that milieu.” In simpler terms, EMC equates to the capability to endure external perturbations while refraining from disrupting the external world

The IEC delineates EMI as the “deterioration in the performance of equipment, transmission channel, or a system due to an electromagnetic disturbance.” Succinctly put, EMI signifies a decline in performance due to external disturbances.

Yet, amidst the IEC’s classifications, some power supply purveyors adopt a different approach. They consider EMI as the concept revolving around how a product influences its operational milieu, while EMC concerns itself with how the surroundings influence the product’s functionality. With the definitions remaining enigmatic, we categorize these activities as either “non-interference” or “tolerance towards external disruptions.”

Let us now delve into three typical disruptions induced by power supplies and the related system designs: conducted emissions, radiated emissions, and harmonics. These disruptions have the potential to compromise or even incapacitate the functionality of electronic equipment operating in close proximity.

The primary concern under the “non-interference” umbrella is emissions, encompassing both conducted and radiated varieties. Conducted emissions pertain to the environmental impact of a product’s operation, channeling energy back to the power source through the power conductors. Regulatory bodies have established upper thresholds for acceptable conducted energy within the frequency range of 150 kHz to 30 MHz. When measuring conducted emissions, a line impedance stabilization network (LISN) intercedes between the device under examination (DUT) and the power source. The LISN establishes a standardized isolation between the power source and the DUT, along with a standardized load for quantifying the conducted energy.

Fig.1 – LISN for the assessment of conducted emissions

Most power supplies are equipped with internal filter components on the input side to suppress conducted emissions stemming from the power supply itself. However, when the power supply interfaces with a system load, inadvertent signals from the system load may flow back through the power supply and manifest at the power supply’s input. If these conducted emissions exceed acceptable limits within the system configuration, the system engineer must introduce components to attenuate these undesirable emissions.

As the name implies, radiated emissions influence the environment where a product operates by disseminating electromagnetic energy. Regulations govern radiated emissions within the frequency range of 30 MHz to 1 GHz, and at times, even higher frequencies. In addition to the system load, radiated emissions can originate from the power supply itself or from the interactions between the power supply and the system load. The conductors entering or exiting the power supply may inadvertently serve as antennas for emitting energy. To address unacceptable radiated emissions, either from the power supply or from the synergy with the system load, filter components are typically installed along the conductors connecting the power supply and the system load. These filter components serve to diminish the energy available for radiation through external power supply conductors. Broadband antennas, operational in an anechoic chamber, are employed to detect and quantify radiated emissions, employing both horizontal and vertical polarization.

Fig.2 – Broadband antenna employed in the monitoring of radiated emissions

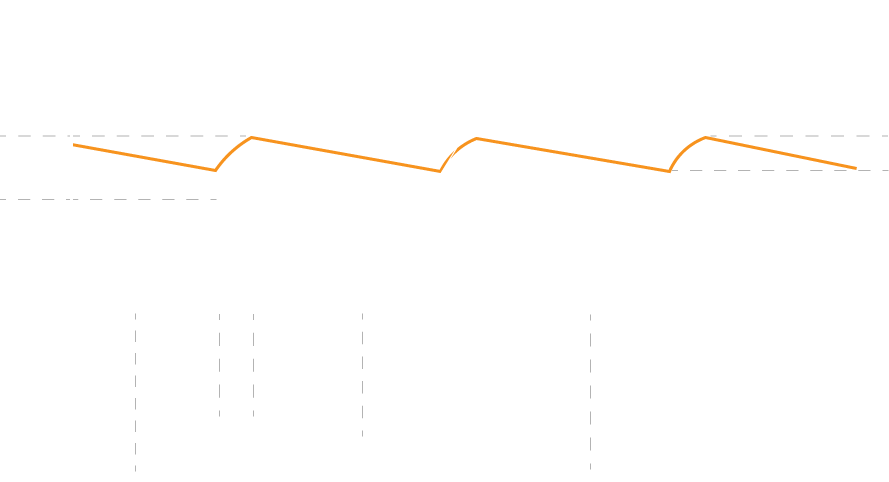

When it comes to harmonics, the concern arises from the fact that many loads connected to AC power sources are not purely resistive. Consequently, even though the source voltage follows a sinusoidal pattern, the load current does not. An illustrative case in point is the load introduced by a power supply, owing to the input bridge rectifier and filter capacitor. The bridge rectifier draws current and charges the bulk capacitor solely during phases where the input voltage surpasses the capacitor’s voltage. This results in a load current waveform characterized by low-duty-cycle pulses occurring at twice the line voltage’s frequency. This low-duty-cycle pulsed load current consumes a substantial amount of energy at harmonic frequencies of the line voltage. Neither the power source nor the line voltage transmission system is optimized to deliver energy at these harmonics, leading to suboptimal system performance. In some power supplies, Power Factor Correction (PFC) circuits are indispensable to curtail the harmonic energy drawn by the power supply. IEC 61000-3-2 outlines the harmonic current specifications, encompassing the 2nd through 40th harmonics, and applying to equipment with rated currents up to 16 A.

Fig.3 – Voltage and current waveforms at the input of an AC-DC power supply

It’s important to note that harmonics are an internally generated disturbance relevant solely to AC-powered supplies, while conducted and radiated emissions pertain to both AC and DC-powered supplies.

The concepts of EMC and EMI are closely linked, and the standardized definitions of these terms may encompass either. In a broad sense, they embody the idea of “endurance against external disruptions while refraining from causing disturbances in the external realm.” While universal consensus on definitions eludes us, regulatory bodies diligently specify and oversee the disturbances. Power supply providers, such as Alexander Electric, possess a deep understanding of these regulatory requirements and can assist their clientele in creating products that comply with them.