This article deals with universal AC/DC converters designed for power supply of industrial and special equipment. Converters have no analogues in the world in combination of wide temperature range, resistance to external influences and small-size low-profile design.

In the modern market of AC/DC power supplies products with operating temperature range of -10 … 70°C and relatively large size are widely represented. In addition, sources with power over 150W often contain such potentially unreliable element, as built-in fan. However, there are operating conditions in industrial and special purpose equipment, which impose special requirements on power supply sources in terms of dimensions and resistance to intensive influence of mechanical, climatic and chemical factors (vibration, extended temperature range, dust, salt spray, etc.).

Radioelectronic equipment for products of Military and Industrial categories usually requires for power supply two to ten ratings of stabilized direct voltages from 3.3; 5; 9; 12; 15; 24; 27; 36; 48; 60V, which are formed from AC 220V voltage with frequency 47…440 Hz. When working with a buffer battery, voltage ratings of 14, 28 and 56 V (taking into account the drop on the isolation diode) are also used.

As a rule, it is necessary to have several sources of stable voltage, galvanically unrelated to each other and to other sources, as part of the required ratings. This is determined by the need to form „floating“ voltage sources, allowing, if necessary, series or parallel connection of output voltages, connection of poles to the device body, redundancy or, to ensure EMC, separation of „clean“ and „dirty“ ground for analog and digital units.

Currently, two structural schemes, shown in Figures 1 and 2, are widely used in the construction of distributed power supply systems.

Fig. 1 – Distributed power system without intermediate conversions

In the first scheme (see Fig. 1), relatively low-power AC/DC modules are connected to the AC input voltage, which immediately, without intermediate conversions, form the output voltages necessary for the equipment galvanically isolated. This structure, in the simplest case, has one AC/DC module, making it a conventional power supply system. If necessary, one of the modules can have a buffer battery on the output to power the most critical parts of the equipment.

Fig. 2 – Distributed power system with an intermediate bus

In the second structural scheme (see Fig. 2) there is a centralized powerful power supply, stabilizer conditioner, which forms a galvanically isolated stable voltage of intermediate bus, such as 24 or 48 V, from the input voltage. If it is necessary to ensure continuity of service, the conditioner forms 28 or 56 V for the buffer battery. DC/DC modules are also connected to the intermediate bus with their inputs, which finally form the above mentioned 2-10 rated output voltages. The issues of their galvanic isolation are easily solved.

Each of the given structural schemes of distributed power supply has its own advantages and disadvantages. The disadvantages of the first structure include the remoteness of converters from the powered loads, caused by the need to eliminate the high-voltage wires of the input network.

However, it is this construction of the power supply system that maximizes efficiency and minimizes heat losses, which is often the determining factor. Since this is a single stage system, only 25% of the total output power is dissipated as heat when the efficiency of each inverter is 80%.

The second design has a great deal of flexibility and unlimited functionality. For example, you can remotely control the individual modules of DC / DC, make them redundant, thereby increasing the reliability of the system, to provide multiple separation of the mains voltage, which in some cases is decisive – for example, when solving complex problems of electromagnetic compatibility or electrical safety (medical equipment). Only in such a structure it is possible to bring converters as close as possible to electronic devices – consumers.

It is easy to notice that the efficiency of such a system is lower than that of a single-cascade system and is equal to the product of efficiency of converters connected in series. Besides, in order to provide high power of the centralized stabilizer during start-up it is necessary to choose it with output power, in 1,5 … 2 times higher than the system power in steady-state mode, which also leads to a decrease in efficiency.

To build power supply systems according to any of the options considered, developers of modern equipment, including special purpose, need AC/DC converters of different power, which have the following design and electrical properties:

Modular AC/DC converters are widely available on the market, mainly from Asian manufacturers, which have almost no competition in terms of price. However, these cheap devices have many features that complicate their application in industrial and special equipment, because the totality of the above properties is usually not achieved.

First, such modules, as a rule, have a design, in which the ratio of the module height to its length is unacceptably high. This causes great inconvenience when such modules are placed in close proximity to powered (low-profile) functional units.

Secondly, several outputs of one module are usually galvanically connected, which makes it difficult to build highly efficient power supply systems and organize „clean“ lands.

Thirdly, most proposed AC/DC modules are based on printed circuit boards with local heat sinks, not designed for efficient heat dissipation to a common flat heat sink. An example is the design of a „computer“ standard ATX power supply. As a result, in most cases of convection cooling and in some cases of air blowing, hardware designers have to provide unacceptably large air gaps on the sides of each module and especially on the top. The presence of a fan in the module design usually results in increased module height, reduced reliability in dust and sand environments, and increased noise and vibration levels.

The compact AC/DC modular converters manufactured by Alexander Electric Group achieve almost all of the above properties. The typical range of AC/DC converters of Alexander Electric Group is represented by Standard, Industrial and Military categories.

Low-cost AC/DC converters of Standard category are designed for power supply of various general purpose industrial equipment. They are made on standard element base, supplied without sealing and operate within the temperature range of -10…70°C. Optimal for most applications the configuration of converters reduces the cost of creating a general purpose power supply system.

Industrial category converters with operating temperature range of -50…85°С are designed for power supply of industrial equipment of different climatic design. Devices are made on component base tested in the extended temperature range and encapsulated in thermally conductive compound that protects elements from adverse external influences. The modules undergo special temperature testing and electrical heat tracing to ensure reliable operation in the hardware.

AC/DC converters of Military category have operating temperature range of -60 … 100°C and are made on custom component base. They are hermetically sealed with a thermally conductive polymer compound and are designed to power industrial and special equipment in the harshest climatic conditions. The modules undergo special types of temperature and limit tests, including electrical thermo-training with extreme on and off modes.

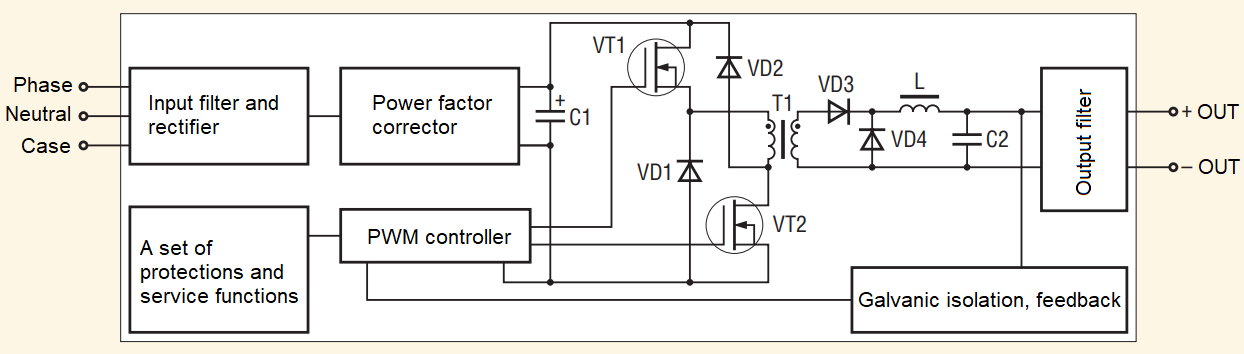

AC/DC converters have been developed for use in various power system configurations. For example, modules up to and including 200 W are optimal as sources in a power system without intermediate conversions (see Fig. 1). They can have up to three output channels and are based on reverse-phase voltage converters with galvanic isolation between input and output (see Fig. 3).

Fig. 3 – Block diagram of modules with output power up to 200 W

Modules above 200W typically have one output channel and can be used as a centralized stabilizer in the structure shown in Figure 2. They are a straight-through, so-called oblique half-bridge structure with galvanic isolation between input and output, shown schematically in Figure 4.

Fig. 4 – Block diagram of modules with output power over 200 W

Modular converters not only have high power density, but also have a special design, designed for a common heat sink base, reducing the required volume for the power supply system.

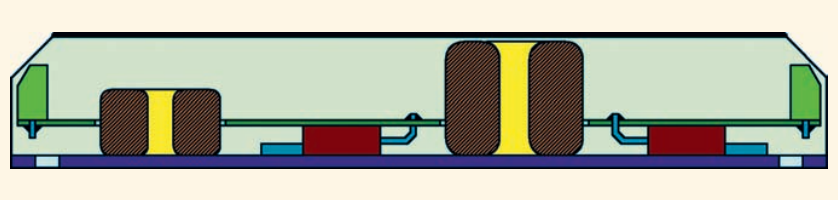

Fig. 5 – Schematic design of the modules

Figure 5 shows a schematic cross-section of the module design. The module is based on an aluminum housing, to which the heat from all heat-loaded circuit elements – power transistors, diodes, transformers, chokes – is transferred. As a result, the body of the module is also a heat sink, which has a good heat dissipation. Converters without additional heat dissipation in normal climatic conditions can supply power of about 200 W to the load, and with a radiator and forced cooling – up to 500 W up to ambient temperature 100 ° C.

The enclosure has mounting holes for mounting the modules on the heat sink; there is also a version for DIN rail mounting. The PCB is protected from mechanical and climatic influences by a thin-walled steel cover. This enclosure design, which covers the transducer elements on four sides, further improves its electromagnetic compatibility with the surrounding equipment. For a more reliable protection against external factors in industrial and special purpose equipment, the transducers are designed with a polymer sealing thermally conductive filling, which prevents damage to the transducer caused by vibration or ingress of dirt, moisture or salt spray.

The printed circuit board of the module has input and output screw terminal blocks; modification with solder pins or flexible mounting leads is also possible.

The described implementation of technical solutions made it possible for AC/DC converters of Alexander Electric Group to confidently compete with similar products of other manufacturers.

The analysis of the modern market of AC/DC converters shows that the products of Alexander Electric Group have all the features required for industrial and special purpose products. High quality of AC/DC converters is achieved by using modern element base and circuitry, design and technological solutions protected by patents and copyright certificates.

Thus, today AC/DC modules of Alexander Electric Group meet the requirements for power supply systems of modern compact equipment of industrial and special purpose and reflect the modern level of high-tech products of the manufacturer that successfully combines the latest technologies and resource saving.