The article describes a method of building AC/DC power supply systems for the line of TESAV series modules, serial production of which was launched by Alexander Electric in 2014. This solution is characterized by high reliability and ability to operate in a wide temperature range. Please note that this series of modules has been discontinued.

The reason for the development of the TESAV line was the growing customer demand for compact AC/DC converters that operate over a wide temperature range and have high reliability and life cycle performance. Apparently, the growing demand is due to the development of technical equipment that must operate in a wide range of atmospheric conditions, including maintenance-free areas. Hence the requirements to the temperature range of AC/DC converters: -60…+125°C.

The most problematic components in AC/DC converters, which limit the operating temperature range, are electrolytic capacitors in the input rectifier and output filters, as well as optronic feedback elements. In addition, condensation forms on individual parts of the inverter during continuous operation at sub-zero temperatures due to the heat generated by the inverter. As a result, the inverter also requires reliable insulation (sealing).

In order to realize these requirements, special circuitry and converter structure were used in the development of the TESAV module range. The new method is based on circuitry without electrolytic capacitors in the output filters and without optronic feedback elements. Transformer feedback solutions, widely used by Alexander Electric in their high-temperature DC/DC converters, were used to realize the feedback. It should be noted that the refusal to use electrolytic capacitors in output filters and optronic feedback elements allows not only to produce AC/DC converters capable of operating in a wider temperature range, but also to significantly improve the reliability of TESAV modules.

To ensure realization of wide-temperature applications and increase reliability, the electrolytic capacitor of the input diode rectifier in the TESAV line is removed from the module’s structural volume and is an external element. Of course, removing the electrolytic capacitor from the power supply module alone cannot increase the reliability of the AC/DC converter, but it does offer a number of advantages. For example, it allows you to choose the necessary capacitor when designing the power supply system, taking into account the specific needs and real power, as well as the temperature and parameters of capacitors in the necessary temperature range.

Figure 1 shows the wiring diagram of the TESAV module, where the input rectifier capacitor is labeled as C4.

Fig.1 – Structural diagram of realization of the way of TESAV module connection

It can be said that it is the removal of the electrolytic capacitor of the input rectifier that made it possible to create a converter with the maximum operating temperature of the housing up to +125°C.

This, in its turn, allowed to considerably reduce the requirements to the cooling radiator, and for power up to 150 W, if the ambient air temperature does not exceed +60°С, to eliminate it altogether.

At the same time, the removed capacitor of the input rectifier operates in the zone of ambient air temperature instead of inside the structure saturated with heat concentrators, which significantly increases its lifetime and, consequently, makes the power supply system as a whole many times more reliable.

Figure 2 shows a graph of the output power reduction for the TESAV200 module as a function of ambient temperature.

Fig. 2 – Graph of dependence of module output power on temperature

In a power supply system based on TESAV AC/DC converters, the rectifier input electrolytic capacitor is still the element with the lowest MTBF. However, when considering the reliability and lifetime values, it should be taken into account that in this case the capacitor failure should be considered as a recoverable parameter and its reliability values cannot influence the lifetime of TESAV AC/DC converters. In addition, it is possible to perform routine maintenance of the capacitor (e.g. by measuring the ripple level) and, if necessary, to replace it.

Thus, TESAV modules provide the customer with the opportunity to create ultra-compact power supply systems based on AC/DC converters, which do not require forced air cooling, and in some cases allow to refuse any radiator at all. At the same time, their reliability and service life are guaranteed to be at the level of DC/DC converters. It should be noted that traditionally for Alexander Electric company the nomenclature of TESAV modules covers a wide power range – 50…1000 W.

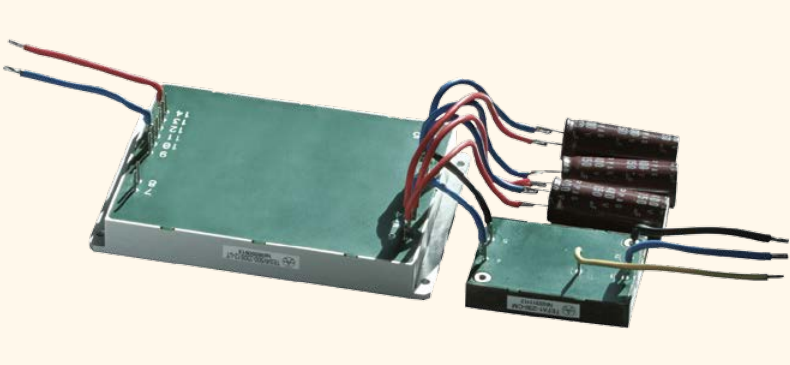

These ultra-compact AC/DC converters, the appearance of which is shown in Figure 3, are designed for industrial equipment and products operating in harsh operating conditions and in particularly demanding applications.

Fig. 3 – Ultra-compact AC/DC converter of the TESAV series

Distinctive features of the converters are:

All TESAV modules have a full range of protection functions: from overcurrent and short-circuit to overheating and overvoltage at the output. Modules with a power range of 100…1000 W feature remote feedback to the load and parallel connection of modules to increase the total power. The modules are available in low-profile housings with a height of 13-16 mm and are filled with thermally conductive sealing compound.

The TESAV modules can be operated either from AC or DC mains. In the latter case, the external capacitor of the input rectifier is not installed, and the input voltage, in order to avoid unnecessary losses on the input rectifier diode bridge, can be fed directly to the inputs provided for this capacitor. The possibility of operation from DC and AC networks, as well as the possibility of selecting an external input filter capacitor for specific needs, make the described converters truly versatile and convenient for use by both designers and users.

It should also be noted that the versatility in terms of AC/DC input network has the possibility to connect both networks simultaneously. This is a great advantage when building uninterruptible power supply networks for particularly demanding applications. For example, for category 1 consumers, including special category 1 consumers, where redundant power supply networks are a prerequisite. In this case, the voltage from the second (redundant) DC network can be supplied via decoupling diodes to the same module terminals to which the external rectifier capacitor (C4) is connected.

Figure 4 shows the simplest power supply system with remote capacitors. Such a system allows the converter profile to be significantly reduced, resulting in an increased energy density. The layout flexibility of such a bundle in equipment with complex configurations of power supply converter volumes is also clearly visible.

Fig. 4 – Example of construction method AC/DC converter with remote capacitors capacitors

All of the above-mentioned advantages of TESAV converters based on a new way of building AC/DC power supply systems, combined with an extended operating temperature range and high energy efficiency, make them unique in the AC/DC converter market.